Technologies are not standing still, neither in medicine nor in space. The field of electrochromic devices is developing in the same way. Even yesterday electrochromic reactions seemed to be the simplest principles of chemical reactions, but today, thanks to new discoveries and in-depth research into the principles of electrochromic reactions in various materials, we have more knowledge about what happens inside an electrochromic device. For example, studies carried out within the walls of our laboratory indicate that the increased degradation of the electrochromic device is caused by improper electrical power supply.

Our chemists and engineers have conducted hundreds of experiments, involved dozens of pieces of equipment and lit up several months of building a model of electrochromic devices. Now, thanks to the modeling, we can model various states occurring in the electrochromic device, analyze the processes arising there with the accuracy available to the used mathematical apparatus. And as a result of our analytical work, we have developed a line of new universal controllers for safe control of electrochromic devices.

The second generation of Controllers for Glass (short for KDS-2) is represented by two models at once and fully meets the requirements for safe and fast electrochromic load control. Controllers of KDS-2 family are designed for use in vehicles. Controller KDS-2 is equipped with two channels with feedback and allows controlling two electrochromic devices connected to it both simultaneously and independently. Controller KDS-2 Mini has only one channel and can control only one electrochromic load, but at the same time it has a minimum size and can be used where there are difficulties in wiring. Controller KDS-2 Mini can be installed, for example, in the car door and prevent dragging wires throughout the cabin.

Controllers of KDS-2 family are universal and can be used practically with any electrochromic devices with supply voltage up to 4 volts and consumption current up to 3 amperes. The KDS-2 controllers can be controlled by push buttons, switches, encoders, serial port commands and even the CAN bus. And for remote control, remote control modules are connected to the controller.

All electrochromic glasses are unique. They vary in size, geometry, properties of electrochromic components and their characteristics change even when using materials from different manufacturers. That is why our controllers are programmed at the manufacturer's enterprise directly under the load with which the controller will work in the future. Thanks to this individual approach, electrochromic devices can be used with KDS-2 controllers without fear of rapid degradation due to incorrect power supply. And most of the user functions of the controller can be reconfigured by the user to suit his needs.

But even now, we have not stopped at the development of technology, including our controllers. There is a constant updating of the program code, improvements and changes are introduced, which allow using controllers KDS-2 in new scenarios. And new information, new electrochromic compositions and coatings, push us to implement improved control algorithms.

Our competencies in research and development of electrochromic devices are not only fixed in patents, but also allow us to provide services in testing or development of new electrochromic systems and devices for our customers and partners. We have the theoretical and practical basis, equipment and qualified specialists for any research in the field of electrochromic systems.

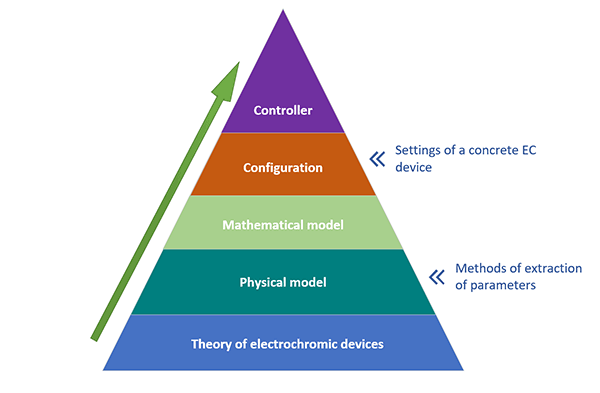

Control systems for electrochromic devices Octoglass are based on the created theoretical base on which the physical model of the electrochromic device rests. The mathematical model created on the basis of the physical model allows to carry out calculation experiments both with the virtual electrochromic device and to investigate parameters of the real sample of the electrochromic system. On the basis of the mathematical model, both characteristics of the electrochromic device to be created and parameters for algorithms to control the device are developed. The obtained parameters are used to configure the control controller for safe control of a specific electrochromic glass.

The application of modeling together with the verification of results in practice allows for more accurate processing of changes in electrochromic devices, configuring controllers for specific products to ensure their long-term operation.